Whenever it comes to exploring green building construction options, natural stone emerges as the first and foremost option among builders, architects, and landscapers. As everyone today is inclined towards green building practices, this option seems to be a clear and concise choice. it has widely been used to build everything from modest residences to the world’s most iconic structures. Being a building material, stone needs almost zero manufacturing and is so tough that stone structures-built thousands of years ago still stand tall today—features only a few present-day “green” products can match.

Despite this, natural stone has been mainly ignored by the green building movement, while ephemeral products made of recycled plastic often carry green labels. Settled, stone has some major environmental influences, but they may not be as influential as you believe, and the stone industry has commenced notable sustainability efforts. This earliest building material may be highly pertinent in today’s green building landscape.

Despite this, natural stone has been mainly ignored by the green building movement, while ephemeral products made of recycled plastic often carry green labels. Settled, stone has some major environmental influences, but they may not be as influential as you believe, and the stone industry has commenced notable sustainability efforts. This earliest building material may be highly pertinent in today’s green building landscape.

Dimension stone refers to a stone that has been cut, as contrary to the crushed stone. This stone has been used as flooring, wall cladding, solid surfaces, and walls along with landscaping and several other applications. Of the projected, 1.88 million tons (1.71 million metric tons) of dimension stone produced in the U.S. in 2011, 808,400 tons (735,000 metric tons) were used by the building sector, as per the data released by the U.S. Geological Survey. The accumulated stone sourced from Brazil, China, India, Italy, and other countries provides almost half of the total exports to the U.S.

Understanding Stone

Stone is known to have all the qualities of green material. It is treated using nearly zero chemicals, it releases no VOCs or dangerous airborne contaminants, and it is water-repellent and hard-wearing. It is also a captivating material that is found to outlast most structures built at present, and it can be recovered from one structure to be reused or recycled in another. Stonewall cladding is deployed on new buildings to match primitive structures, and in regions that face large temperature changes. Stone can also be utilized as the thermal figure for space heating and cooling.

Stone is known to have all the qualities of green material. It is treated using nearly zero chemicals, it releases no VOCs or dangerous airborne contaminants, and it is water-repellent and hard-wearing. It is also a captivating material that is found to outlast most structures built at present, and it can be recovered from one structure to be reused or recycled in another. Stonewall cladding is deployed on new buildings to match primitive structures, and in regions that face large temperature changes. Stone can also be utilized as the thermal figure for space heating and cooling.

Types of stone and their applications

The primary natural stones available today are granite, marble, sandstone, limestone, and slate, but there are several others, like soapstone, basalt, and quartzite.

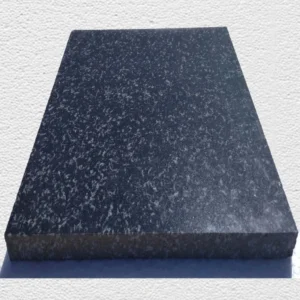

Granite

Granite is a pyrogenic rock developed when molten magma cools gradually under high pressure far deeper in the crust of the earth. This natural stone is composed of alkali feldspar, mica, quartz, and other elements. True granite is known to have tightly combined mineral grains that give a uniform, speckled look to the granite surface.

Granite is a pyrogenic rock developed when molten magma cools gradually under high pressure far deeper in the crust of the earth. This natural stone is composed of alkali feldspar, mica, quartz, and other elements. True granite is known to have tightly combined mineral grains that give a uniform, speckled look to the granite surface.

True granite is composed of quartz, plagioclase feldspar, alkali feldspar, mica, and other minerals, but other fiery rock and metamorphic rocks, such as gneiss, are also marketed as granite. This type of granite has tightly constituted mineral grains that give it a dappled, but even, looks.

Granite is employed for interior décor applications, such as walls and countertops, as well as exterior applications like cladding, landscaping, flooring, and paving. Due to the changing quantities of quartz and other minerals, granite may have a dissimilar density, strength, porosity, and hardness, considering the type of the stone.

Limestone

Limestone is essentially a sedimentary rock formed majorly by the deterioration of earliest organisms that accrued on seabeds and were compressed under pressure over time. Limestone is known to have 50% calcium carbonate (CaCO3), with other types of calcium, magnesium, silica, and other minerals making up the rest. Travertine, another kind of limestone, is created midair when CaCO3 hastens out of mineral springs, mostly near hot springs.

Limestone is essentially a sedimentary rock formed majorly by the deterioration of earliest organisms that accrued on seabeds and were compressed under pressure over time. Limestone is known to have 50% calcium carbonate (CaCO3), with other types of calcium, magnesium, silica, and other minerals making up the rest. Travertine, another kind of limestone, is created midair when CaCO3 hastens out of mineral springs, mostly near hot springs.

Limestone is utilized for interior surfaces, flooring, exterior cladding, landscaping, and paving. Limestone tends to feature an even, non-crystalline structure but is susceptible to chemicals, so when it gets exposed to acid rain, the boundaries of limestone details can turn curved over time. There are three marks of limestone, Type 1 (lesser density), Type II (mid-level density), and Type III (high density). These characteristically available in white, beige, gray, pink, and other shades, based on the number of minerals. With respect to 3 or 4 on the Mohs hardness scale, limestone is usually too lax to be cultured, and its compressive strength remains less than granite.

Marble

Marble refers to a metamorphic rock created when limestone, dolomite, and parallel sedimentary rocks get exposed to heat and pressure over a period of time. Contrary to limestone, marble features veins caused by minerals crystallized during its development and comprises small fissures.

Marble refers to a metamorphic rock created when limestone, dolomite, and parallel sedimentary rocks get exposed to heat and pressure over a period of time. Contrary to limestone, marble features veins caused by minerals crystallized during its development and comprises small fissures.

Alike limestone, marble is used for interior surfaces, exterior cladding, landscaping, and flooring. It classically appears in white, pink, red, and gold and is a soft stone, like limestone, at about 3 or 4 on the Mohs scale; compressive strength is also likewise, sitting at 7,500 psi. And marble is also susceptible to chemicals, so general kitchen tumbles can feasibly damage and stain the surface lest sealed.

Sandstone

Sandstone is a sedimentary rock formed when sand, major grains of quartz and feldspar, is put under pressure. Calcium carbonate, iron oxide, and silica between the grains bind them together similar to cement. Sandstones that face extra heat and pressure transform into quarzitic sandstone and metamorphic rock quartzite over time.

Slate

Slate is a metamorphic rock created from the layers of clays or volcanic ash changed under heat and pressure over years. Created using quartz, aluminum, chlorite magnetite, and other minerals, slate contains a solid, layered nature that enables it to break along planes to result into thin, durable slabs.

Environmental Concerns

Many people think the quarrying process of marble and other natural stone is similar to mining. They also think that granites pose a radioactive risk, and transportation power need to shift the heavy stone to the application area plays a crucial role.

There is a considerable difference between mining and quarrying. In mining, various elements are extracted from the deeper layers of the earth followed by concentrating them at the surface. During mining, different types of materials are extracted other than the primary material. In addition, the entire process of mining is quite energy-intensive, and its runoff contains harmful byproducts that pose threat to air and local groundwater.

On the other hand, quarrying involved the extraction of rock in large concentrations at the surface. The major environmental issues involved in this are heavy noise, infrequent runoff of solids, and scrap piles. These are minor issues that can be managed in several ways. For example, the sites can be reused, filled is placing waste from production to carve out usable land, or, in some scenarios, turned into lakes.

Are countertops radioactive?

In the year 2008, The New York Times published a post, “What’s Lurking in Your Countertop?” that stated that granite countertops discharge radon—a neutral, unscented, cancer-causing radioactive fume. Though the article stated that the huge majority of granite countertops are harmless, the fright got attention on the Internet, and granite’s link to radon was paved. Peer-checked, separate researches achieve that radon does not present a considerable risk in the vast majority of granite or slate countertops, but granite is a natural product, and just as your home may sit over a radon flashpoint could possibly possess radioactive cumulative, it is likely that a chosen product may release radon as well. Even then, however, a “hot” countertop is very unlikely to pose a threat based on usual household ventilation rates, derived from other studies.

Despite this, no traces of carcinogens are acceptable, so discovering a way to put an end to this is the best for the industry. Some firms have started their own testing now—but it would be almost impossible to test all granite due to high costs and the problems of monitoring today’s stone through the industry.

Industry initiatives

The stone industry is deploying advanced quarrying and production procedures that enhance the efficiency of stone generation and lower its environmental effect. For example, during the quarrying of stone, cutting the stone with diamond wire saws results in lesser waste and dust; in the shop, CNC machines help in optimizing production and minimizing waste; and on buildings, stripper, lighter products are being applied that substitute bigger, less resource-intensive slabs.

The stone industry is gradually embracing its requirement to engage with the green building standards, but there is still a lot of work to do. Old processes need to be revised. This appointment should continue to enhance the stone’s environmental footprint. There is no ideal building material, but the stone is getting closer.