Quality control for delivering products with zero defects

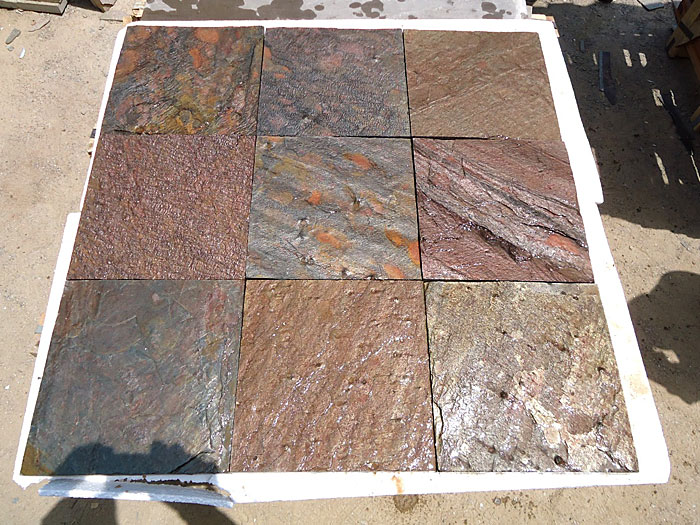

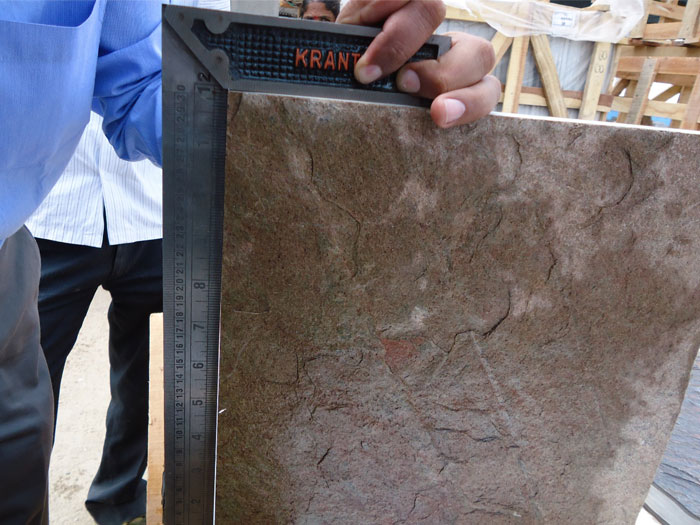

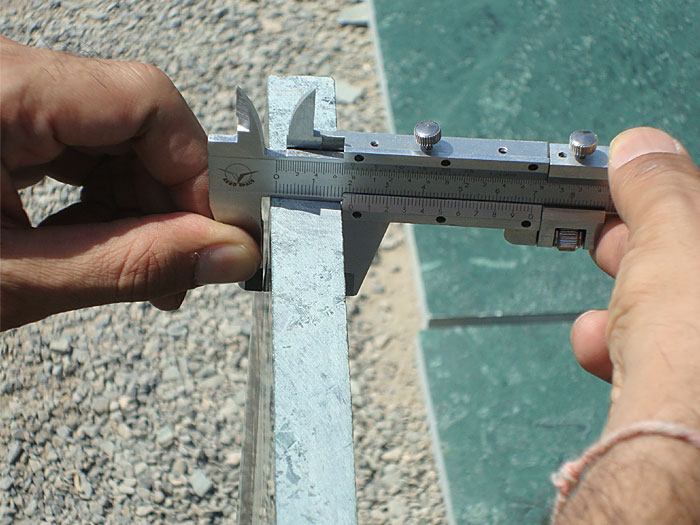

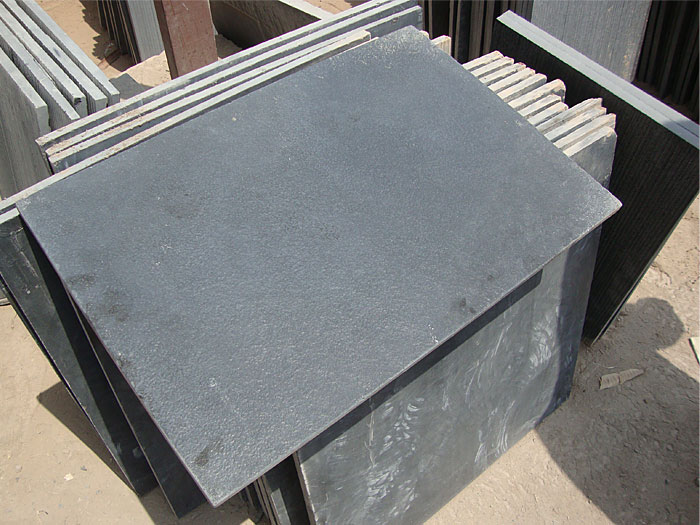

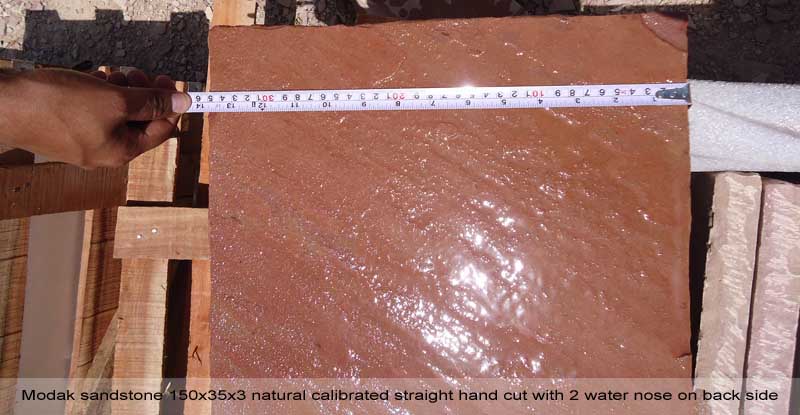

We, at Regatta Universal Exports, understand what is needed by our natural stone buyers. So, the process starts mid-way during the production process. We process marble, slate, quartzite, granite, limestone, and sandstone tiles, slabs, and natural stone. Our head office receives photos of production for checking. Each customer’s specification is checked. If some changes are required, these are implemented. After production is complete, the local quality officer sends a report to the head office. Around 30% of the containers are checked by quality control officers stationed at the head office. They travel in different parts of India, where ever the containers are packed, to check for quality. Every container with a special finish is also checked by quality inspectors. From quality control procedures to quality management practices, we leave nothing unnoticed.

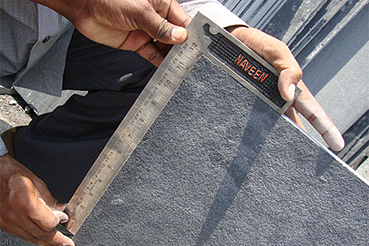

Pre and during production quality control checks

Quality is always a prerequisite at Regatta Universal Exports. From extracting the rough blocks to processing them at various levels, loading them in containers, and transporting them to the destination, we abide by globally accepted quality parameters to ensure an avant-garde stone buying experience for our clients.

Our years of industry expertise and a team of skilled and experienced professionals gives us a competitive edge in the field of natural stone manufacturing and supply. In order to maintain an optimum level of client satisfaction, we perform a thorough evaluation of whether the client’s requirements are met or not, and the changing needs of the client are then conveyed to the production team, where product improvement and certification jobs are carried out.

At Regatta Universal Exports, we follow a unique quality control system that comprises strict manufacturing procedures to ensure flawless products. We have a team of qualified, experienced, and dedicated professionals, who ensure the effectiveness of our quality control measures. We keep ourselves updated with new trends and equipped with modern techniques in order to deliver the best products to our customers. Our quality control analysts put rigorous checks at every stage of production. At Regatta, we ensure the delivery of only quality products to our clients.