Like other industries, the natural stone industry has also affected due to the omnipresence of the most lethal COVID-19 or coronavirus for the last 5-6 months. Sometime back, the production of natural stone like marble, granite, sandstone, quartzite, and limestone, halted suddenly. Packed stone crates stuck at shipping ports are still waiting for clearance. A large number of people involved in stone processing practices have gone back to their native places. Now, the story has changed and the whole world is back to normalcy after lifting of lockdown. With the phase-wise lifting of lockdown permitted by governmental authorities, the Indian natural stone industry is back in action with some restrictions and adoption of preventive measures. Read the content and find out the challenges and situations faced by the Indian natural stone industry in the form of some quotes.

Preventive measures amid challenges face by the industry

After going through a lean phase of economic downturn and halted production, the industry is ready to move ahead. The current situation and challenges faced by stakeholders involved in the global and Indian natural stone industry are the most prevalent things around. By sticking to the clause of maintaining 2-meter social distancing, stone companies are ready to operate. By following workplace hygiene and other prevention measures, the natural stone industry in India is ready to cater to the demand of B2B buyers for marble or granite slabs, tiles, blocks, and other stone articles. In the present scenario, the following are some of the obvious challenges that the natural stone industry has to overcome at all. These include:

- Exports are being affected badly due to a fall in demand.

- Most of the projects are suspended.

- Logistics is another issue due to uncertainty in the sea and air cargo.

- Indian suppliers are matching B2B buyers’ demand for natural stone products.

- Preference is given to the safety of all employees from coronavirus.

- Balancing of staff is being taken off furlough with incoming work.

The pulse of natural stone industry in times of Covid-19

Lots of things have been changed in the last few months. Even, the way of living inside the home was a common phenomenon. Since the start of the lockdown and lifting of lockdown in phases, the Indian natural stone industry has faced different situations and affected the lives of people associated with the industry directly. The following are some of the quotes showing how things are changing rapidly in India in the times of Covid-19.

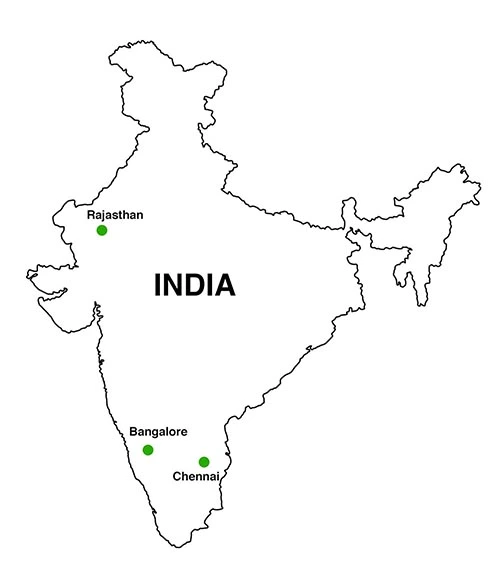

“Our factory in Shoolagiri, Tamil Nadu is geared up and ready to serve the customers of imported marble again. The coronavirus scares have led to a slower flow of customers to our factory. We are still witnessing interest from the buyers as these are people who need the material. Some customers are still hesitant to come across the state border and visit our factory to place new orders. Some of the past orders have not yet been dispatched because the buyers are facing restrictions particular to the area they stay in. Though our sales have seen a reduction in the coming months we are positive that orders will pick up through visits to the factory to select the material.”- Sourabh Agarwal, Millenium Marbles, India

“While the lockdown in India still continues, the authorities have started giving permission for operating to stone companies who can prove they need to fulfill pending orders. Orders and inquiries are now coming from China and other countries, and self-inspection is becoming the norm in cases where the buyer-supplier relationships are well established. Further easing of the situation is expected in about 2 weeks.” – N.Mahesh, Devinarayan Granites, India

“The stone companies are working with great difficulties to fulfill orders. The virus is still spreading and has created a severe shortage of skilled labor in the quarries and factories because the people have gone back to their villages. There is no consistency of supply from the quarries. There are also restrictions in the movement of people from one state to another, which makes workers reluctant to return. In transport, the problems come from the reluctance of drivers to work due to fear of catching the virus.” – Tirumala Rao, Sterling Stonex, India

“From 25th of March, the Indian stone industry, as every other Indian industry has suspended entire operations owing to Government directives to contain the pandemic. This includes quarry activities, processing facilities, allied logistics, administrative offices. The initial spurt in demand for Indian stones owing to disruption of Chinese supplies was diluted as the target markets themselves got locked down. Staffers working from home are floating inquiries, with the knowledge that production and supply worldwide will occur only once the crisis is over. The world is on a standstill. Construction and hence stone trade can wait, humanity has to go on, safety first is the current mantra.” – Haseena Zaki Chakkiwala, Quality Marble Exports, India

To sum up

All stakeholders in the Indian natural stone industry have affected. From marble stone factory to granite stone quarries and from sandstone processing units to slate packing units, the natural stone business went through various challenges. Things are improving day-by-day and Indian natural stone suppliers are back to the business and are ready to cater to the changing needs of B2B buyers. B2B buyers from the rest of the world can opt for Indian natural stone tiles, blocks, slabs, and stone articles for various commercial purposes.