In recent times, deteriorating air quality has become a matter of concern in almost all popular cities across the world. There was a time when very few people concerned or put much belief into it. With the increasing focus on greener construction and attaining different types of LEED certifications and points, Indoor Air Quality, or IAQ has been getting more attention these days. As the use of natural stones like white marble is quite common in today’s structures, it is necessary to determine its relationship with the indoor air quality.

In a construction project which is near to its completion, particularly the surfacing, the most commonly known term around that is “natural”. This usually refers to the use of natural materials like white granite or white marble for flooring and other surfacing applications along with the chemicals that are used to clean these surfaces once the installation is done. In some cases, these surfacing materials are not handled properly which is known to affect the overall indoor air quality.

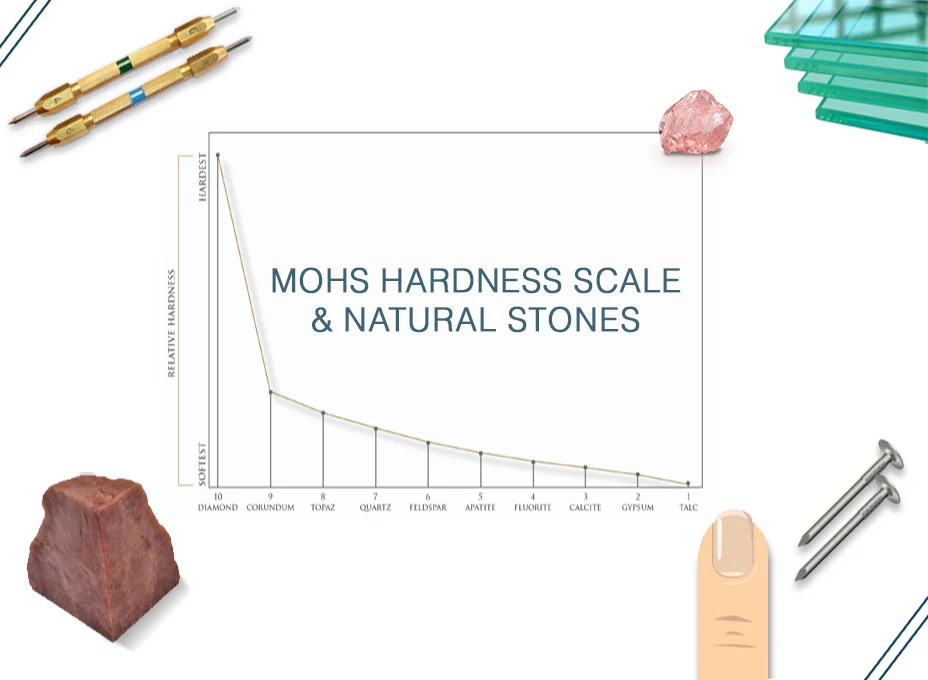

The use of natural stones in surfacing activities is nothing new as they have been used extensively in both residential and commercial structures worldwide. Be it granite, marble, sandstone, limestone, slate, or any other natural stone, they are used in a variety of architectural applications.

What is the relation between natural stones like white marble and indoor air quality?

Before getting to know how natural stones and indoor air quality are interconnected, it is necessary to know the primary drivers of bad indoor air quality. From an architectural point of view, any materials that release Volatile Organic Compounds (VOCs) are found to negatively affect indoor air quality.

There are different types of products that are known to discharge VOCs like carpets, engineered and hardwood flooring, cabinetry, adhesives, furniture, adhesives, and wall paints. One of the biggest perpetrators behind a contribution to VOCs is formaldehyde which is widely used in a variety of composite wood products. Different types of chemical solvents are present in adhesives and paint that discharge VOCs into the air.

However, in the case of natural stone like granite, white marble, or any other natural stone, there is no such issue since all these materials are natural.

One wonderful example is the comparison between carpeted flooring and a natural stone floor done using granite tiles. The carpet, except certified otherwise, is highly likely to discharge a bunch of VOCs into the air, primarily from the adhesives used to follow the carpet and pad to the subfloor along with the latex binder which locks the strands of the carpet to the carpet base itself. Now, compare it with a natural stone floor that contributes to zero VOCs, and install it with a zero VOC adhesive and you get the best quality product in terms of Indoor Air Quality improvement.

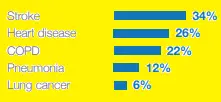

Of the total 4 million premature deaths that happen every year from exposure to indoor air pollutants, the causes are categorized as follows:

In addition, the cost of cleaning and replacing carpet after every few years would simply outweigh the installation cost of a lasting natural stone surface.

Below are some of the conditions that need to be met in terms of good indoor air quality.

| Particulars | Conditions To Be Met |

|---|---|

| Particulate Matter | 10 micrometers or less in diameter: 50 ug/m3; 2.5 micrometers or less in diameter: 15 ug/m3 |

| Carbon Monoxide | Less than 9 ppm |

| VOCs | Less than 500 ug/m3 |

| Fomaldehyde | Less than 27 ppb |

| Carbon Dioxide | About 700 ppm above outdoor air levels (typically about 1,000 to 1200 ppm) |

| Moisture | Below 60%, ideally between 30% and 50% |

| Temperature | 68.5°F to 74°F (winter); 75°F to 80.5°F (summer) |

Let’s find out different types of natural stone flooring and their effects on indoor air quality.

Granite

When it comes to choosing from the best flooring materials for indoors, granite emerges as a wonderful choice due to many reasons. Due to its high level of durability, it remains a favorite choice for flooring in different types of residential and commercial projects.

In terms of indoor air quality, granite flooring is known to be a great choice for people suffering from asthma or allergies. If your entire home has granite flooring, you are less likely to get exposed to allergens. The optimistic effects can really do much more than reducing the frequency of getting a runny nose or sore throat. The EPA terms poor indoor air quality as a grave health concern. The longstanding effects of living in a home with poor indoor air quality are augmented risks of cancer, respiratory illnesses, and cardiovascular diseases.

Marble

Another popular flooring surface material is a marble. Be it white marble or black one, its usage doesn’t seem to exhibit any respiratory issues in humans. Being a hard stone flooring, marble flooring is easy to clean and it doesn’t emit any harmful gases or chemicals in the air which makes it a great choice for both residential and commercial flooring applications.

One big advantage with marble flooring procured from top marble exporters is that it remains cooler even in harsh summer which negates the likelihood of any harmful gas emission due to high temperature. Overall, marble flooring is considered a safer bet for indoor architectural applications.

Sandstone

Primarily used for outdoor paving, wall cladding, and other decorative applications, sandstone always remains a hot favorite choice of architects, homeowners, contractors, and builders. This natural stone has been used for many years to spruce up the décor of any outdoor space.

The Bottom Line

At a time when the world is reeling under the clutches of poor air quality due to rapid industrialization and greenhouse emissions, natural stones emerge as a versatile choice for flooring and other architectural application. As indoor air pollution is found to be 10 times more harmful than outdoor air pollution, choosing the right flooring material is necessary.

Kandla Grey Sandstone Natural Palisades[/caption]

Kandla Grey Sandstone Natural Palisades[/caption]

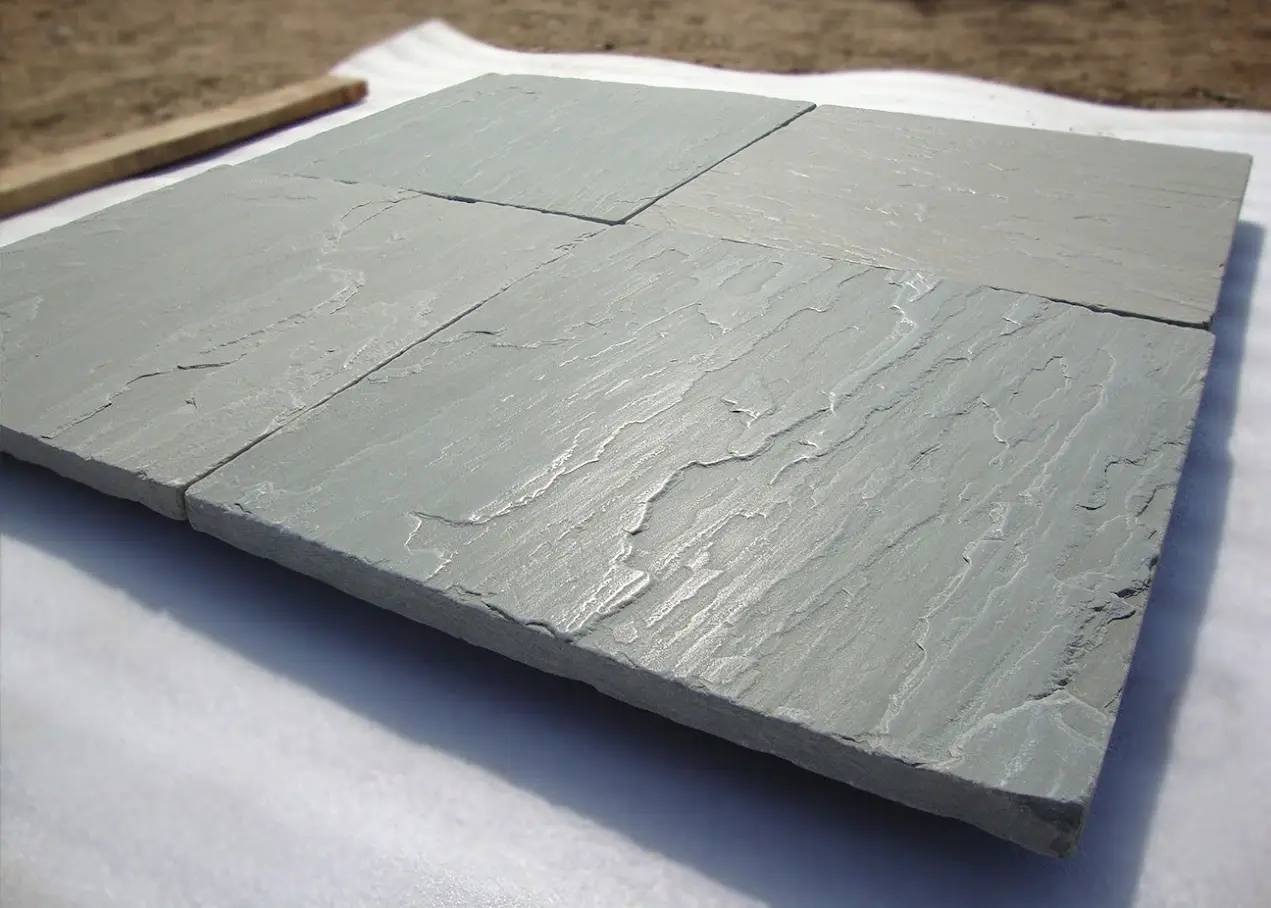

Kandla Grey Sandstone Natural Sandblasted Brushed

Kandla Grey Sandstone Natural Sandblasted Brushed

Kandla Grey Sandstone Natural Brushed Tumbled

Kandla Grey Sandstone Natural Brushed Tumbled