Stone of the month: Sagar Black Sandstone

April 13, 2022 AdminIndia is a major producer of natural stones such as granite, marble, sandstone, limestone, slate, quartzite, and other types. Many quarries may be found around the country, producing high-quality stones that are shipped to other countries. Sagar Black Sandstone is one such renowned stone. This neutral-shade sandstone, which can be found in the northern region of the country, is a popular choice for both residential and commercial projects.

Sandstone’s popularity has risen in recent years as a result of its remarkable features such as hardness, weather resistance, durability, and adaptability. Sandstone is commonly used for wall cladding, garden paving, flooring, countertops, sinks, monuments, pool coping, and other similar applications. The Sagar Black Desert Sandstone is one of several varieties of sandstones that originate in the country’s central regions. It is also known as Saugor Black, Kalahari Black, or Black sandstone.

Sandstone is well-known for its consistent strength, toughness, and slip-resistant properties. This stone has the potential to withstand the worst weather conditions while also increasing the value and aesthetic appeal of any home. The building of Petra is one of the most remarkable examples of sandstone used.

What is Sandstone?

Sandstone can be termed as a sedimentary rock primarily made up of quartz dust. However, it may also contain major levels of feldspar, along with silt and clay. Quartzose sandstone refers to a kind of sandstone that has over 90% of quartz. If there is over 25% feldspar, the sandstone is called arkose or arkosic sandstone. Argillaceous sandstone, on the other hand, is defined by the presence of a significant proportion of clay or silt.

It is the mineral composition of sandstone that awards colors to the sandstone. The color band of Argillaceious sandstone varies from gray to blue. Since it is inclusive of the light-shaded elements, sandstone is typical of light colors. However, sometimes, the abundance of iron oxide rust lends a darker shade to the sandstone.

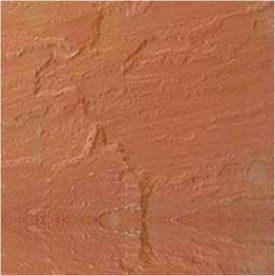

Boasting a dark greyish-black color tone, this Indian sandstone not only looks pretty but also has superb physical properties. Some of the prominent ones are excellent weather resistance, low water absorption, mechanical strength, and durability. Be it an indoor application or an outdoor one, Sagar Black Sandstone is truly the best performer in the category.

Its major application areas include exteriors, wall cladding, flooring, ornaments, building stone, pool coping, monuments, paving stone, and sills.

Major Features of Sagar Black Sandstone

- Extremely durable stone largely stone in wall cladding

- Features unmatched hardness

- An inherent premium appeal

- Available in diverse sizes and finishes

Mining of Sagar Black Sandstone in India

The sandstone mines in the Sagar region of Madhya Pradesh are mostly used to produce this black-colored sandstone. Several natural stone quarries dot the landscape, producing various types of Indian sandstone, including Sagar Black Sandstone.

It’s worth noting that these stone processing plants are adjacent to quarries, resulting in cost savings that are passed on to B2B tile purchasers around the world. A variety of machines are used to prepare the stone in various ways, making it suitable for both indoor and outdoor use.

India is one of the largest producers of Sagar black sandstone. Several sandstone providers and exporters in the country provide high-quality sandstone to countries such as the United States, the United Kingdom, the United Arab Emirates, Denmark, Norway, Australia, Germany, and others.

Processing Unit

Cutting the raw blocks into standard and custom-sized slabs is the next stage of Sagar Black sandstone processing. The slab’s specific dimensions are determined by the type of stone used. Gangsaw slabs and cutter slabs are the most common types of slabs. Tiles, on the other hand, can be made on-demand.

Sandstone is further processed using special blades and gear that turn blocks into slabs of various sizes. Sandstone makers and exporters can now save money and time while boosting quality thanks to recent improvements in the natural stone processing business.

This amount of processing is carried out to bring the sandstone as close to perfection as possible before it is used. Another advantage of this process is that it makes slab transportation easier.

Finished Material

The most important thing to remember is that sandstone may be processed in a variety of ways to achieve a certain surface quality. The final finish choice is determined by the precise application of the stone once it has been processed. The following are the most popular sandstone surface finishes:

- Natural

- Brushed

- Bush hammered

Sizes

The most standard sizes of Sagar Black Sandstone are:

- CUTTER SLAB 120-190 CM X 90-60 CM

- TILES 30 X 30, 60 X 30, 60 X 60 AND 60 X 90 CM

- PALISADE 10-12 X 12-25 X 30-250 CM

- WALL CLADDING 100 X 25-45 X 5 CM

- STEP BLOCKS 75-200 X 35 X 15 CM

- THICKNESS 2-6 CM

Finishes

Surface finishing is extremely valuable since it allows architects to exactly find all of the quirks of the stone material. There are a variety of reasons why surface finishing is so crucial. These are some of them:

- Natural calibrated machine cut and hand-cut

- Brushed machine cut and hand-cut

- Natural + brushed calibrated machine cut (MC) and hand-cut tumbled

- Honed calibrated machine cut and hand-cut

- Honed +sandblasted calibrated machine cut and hand-cut

- Bush hammered calibrated machine cut

The Conclusion

Sagar Black Sandstone has a unique visual aspect due to its greyish color tone. Furthermore, the versatility of this sandstone makes it an excellent choice for modern architecture.