Upgrading indoor and outdoor domestic structures is a basic need to spruce up your living space. There are lots of natural stone colors widely used for elevating existing and upcoming interiors and exteriors. When it comes to having style, appearance, and performance at lower costs, a unique limestone color matters the most. From black to green and from pink to grey, a long list of limestone colors give natural stone enthusiasts an edge. With the content, readers will be able to know more about the most popular limestone tile colors that are suitable for redefining any sort of wall and floor architecture at home or office.

Wall and floor tiles redefined with limestone color

Every domestic and commercial architecture demands beauty and perfection from natural stone surfaces. Quarried from North and South Indian limestone quarries, colorful limestone tiles are processed and shaped professionally at different limestone factories in the south and north India. With loads of chemical and physical properties, limestone is a superb industrial construction material as it can cope with harsh thawing conditions and freezing temperatures. That is why it is widely demanded in all parts of the world, especially the Middle East and European countries. Although it is used for floor tiles, yet the use of limestone as wall material is on the rise. This stone product delivers a rustic, unsophisticated, and timeless appearance to the ambiance around.

As far as the recommended usage of limestone is concerned, this natural stone is vital for building stone, countertops, steps, pool copings, sills, sinks, monuments, and ornamental stone.

- Standard limestone tile sizes: 30×30, 60×60, and 60×90 and 60×120 cm

- Standard limestone tile thickness: 2-6cm

- Popular limestone polishes: Natural calibrated, honed calibrated, and natural + brushed calibrated machine cut (MC) and hand-cut (HC) tumbled

The following are some of the popular limestone color types that natural stone lovers can use to make things happen in their favor. All mentioned-below color types have been procured from North and South India quarries.

Black limestone tiles

Real name: Lime black limestone

Additional Names: Andhra black, Cuddapah black, Madras black, black desert, and Kudappa stone

Destination of origin: South India

Color: Black

Surface description: Black-hued limestone with a rough texture

Recommended Usage: Interior and exterior designing

Blue limestone tiles

Real name: Kota blue limestone

Additional Names: Kotah Blue and Kota Grey Limestone

Destination of origin: Kota, Rajasthan, India

Color: Blue

Surface description: A light blue and grey surface plus delicate shades of yellow and green

Recommended Usage: Interior and exterior designing

Brown limestone tiles

Real name: Kota brown limestone

Additional Names: Kotah Brown, Kota brown natural, and Kota stone brown limestone

Destination of origin: Kota, Rajasthan, India

Color: Brown

Surface description: Light brown surface with subtle shades of green and yellow

Recommended Usage: Interior and exterior designing

Grey limestone tiles

Real name: Kurnool grey limestone

Additional Names: Kurnool limestone

Destination of origin: South India

Color: Grey

Surface description: Grey-colored limestone surface with a rough texture

Recommended Usage: Interior and exterior designing

Pink limestone tiles

Real name: Lime pink limestone

Additional Names: Pink Lime India and Pink Lime

Destination of origin: Nalgonda District, Telangana, India

Color: Pink

Surface description: Pink-colored stone with clearly visible striations

Recommended Usage: Interior and exterior designing

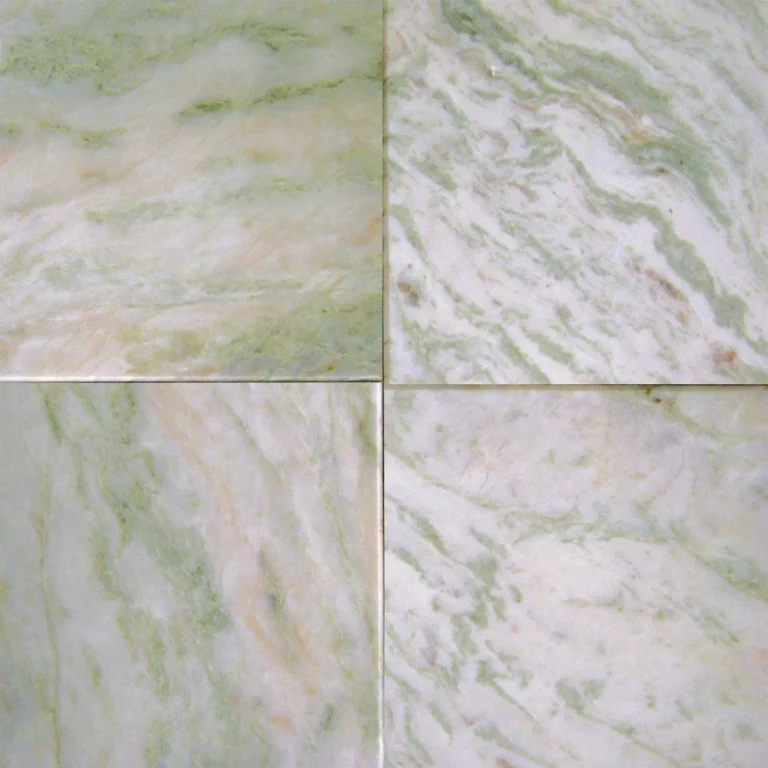

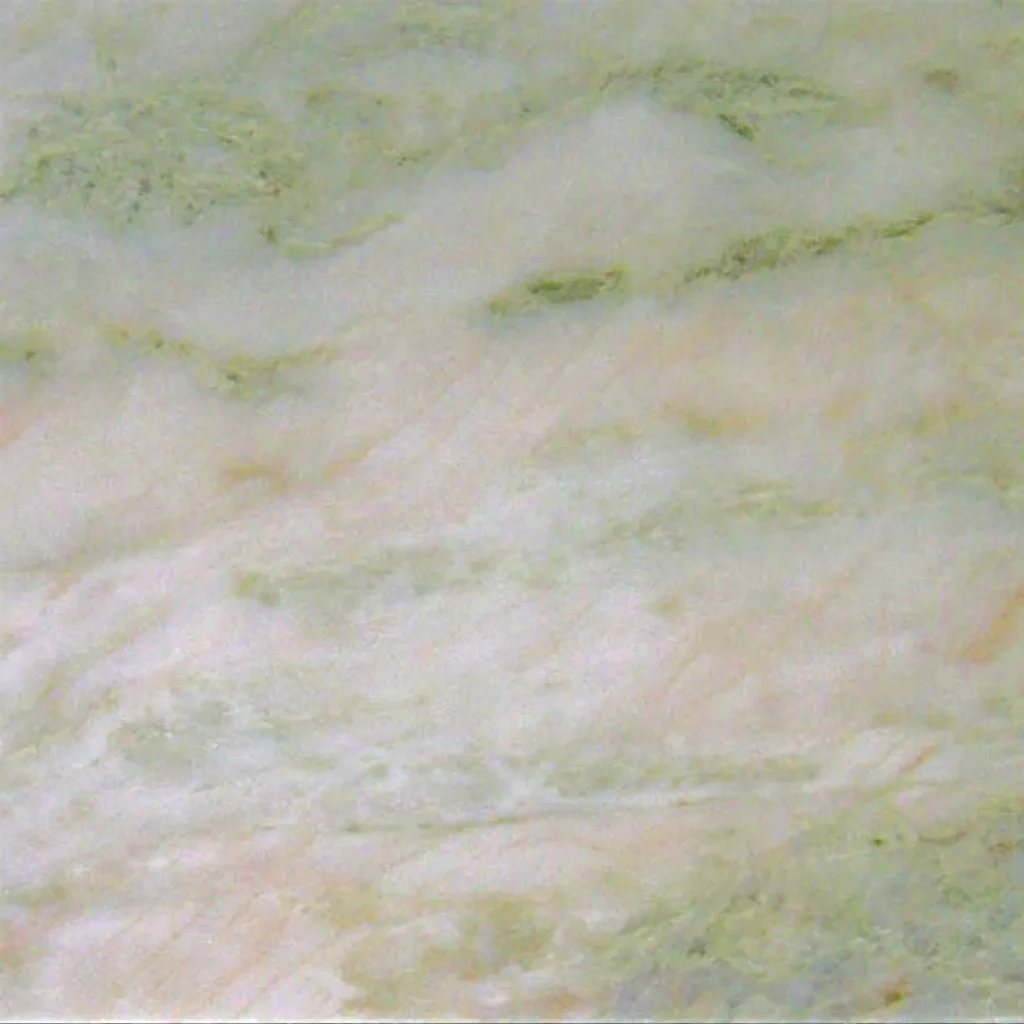

Green limestone tiles

Real name: Lime green limestone

Additional Names: Jaisalmer green limestone

Destination of origin: Rajasthan, North India

Color: Green

Surface description: Pale green surface with various striations

Recommended Usage: Interior and exterior designing

Yellow limestone tiles

Real name: Tandur yellow limestone

Additional Names: French vanilla limestone, tandoor yellow limestone, Shabad yellow limestone, tendur yellow limestone, and tandur yellow limestone

Destination of origin: South India

Color: Yellow

Surface description: Light yellow-hued surface with subtle texture and rustic looks

Recommended Usage: Interior and exterior designing

All these tile types in limestone color from a leading Indian limestone supplier are easily available, B2B buyers can place an order in bulk. These limestone colors are simply synonymous with modern style, trendy look, and performance. From subtle texture to anti-climate ability and from durability to color consistency, there are lots of features that make limestone tiles fit for landscape designing.

r.

Whether B2B limestone buyers are searching for floor tiles in an antique pattern, French pattern, herringbone pattern, or spiral pattern from a competitive market, Indian limestone suppliers from India overcome all expectations in a professional and amicable manner.