Indian sandstone has been traded internationally for several decades. Long before outdoor living spaces became a design trend, Indian sandstone was already being used in public walkways, heritage restoration, courtyards, and large-scale landscaping projects across the UK, Europe, and other global markets. Today, Indian sandstone slabs and Indian sandstone paving remain a preferred choice for importers who value durability, natural aesthetics, and consistent supply.

This article is written for stone importers, wholesalers, and project buyers who want clear, useful information—how Indian sandstone performs, which variants are most reliable, and what to look for when choosing an exporter such as Regatta Universal Exports, a manufacturer and global supplier of Indian natural stone with more than 25 years of experience.

Indian Sandstone as a Material: What Matters in Real Projects

Indian sandstone is a sedimentary stone formed from compressed sand particles, largely quartz-based, that were naturally bonded over time. The material quarried in Rajasthan and parts of central India is generally tougher in comparison to other regions’ sandstone. In general, the toughness of sandstone depends on its quartz content and how consistently it is processed.

From an importer’s point of view, Indian sandstone continues to be a top choice because it holds up well outdoors, especially when used in pedestrian areas. Riven surfaces provide natural grip without additional treatments, and the stone does not deteriorate suddenly when exposed to weather. It tends to wear gradually, which is exactly what contractors and local authorities prefer.

Indian Sandstone Slabs vs Indian Sandstone Paving

Although the terms are often used interchangeably, slabs and paving serve different purposes.

Indian sandstone slabs are generally supplied in larger, calibrated formats. They are widely used in:

– Commercial patios and terraces

– Contemporary outdoor designs

– Projects where clean layout lines are required

Indian sandstone paving is usually supplied as mixed-size paving sets or standard tile sizes. It is commonly specified for:

– Residential gardens

– Footpaths and pathways

– Traditional or rustic landscaping

Both formats can be supplied with natural riven surfaces, honed finishes, or textured treatments, depending on the market and application.Shape

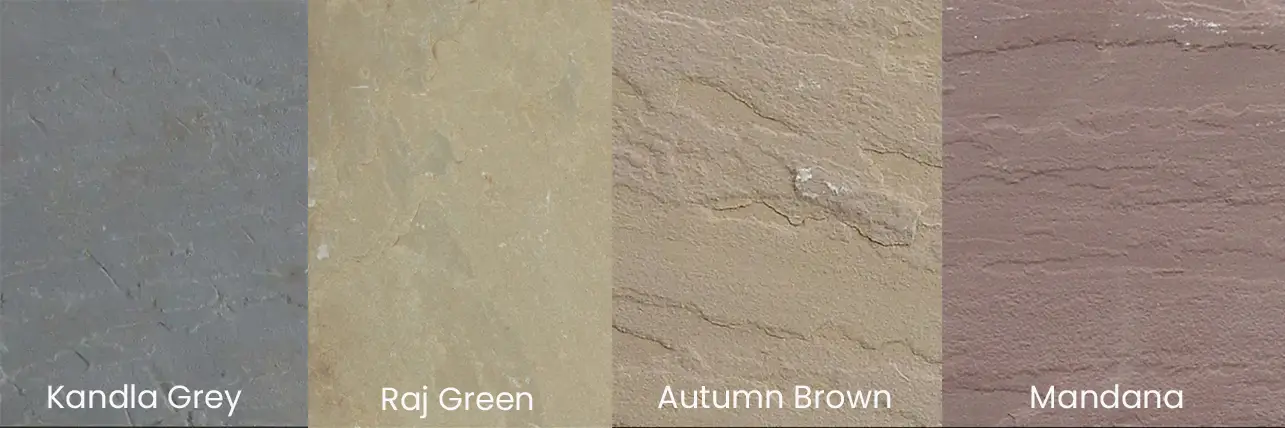

Popular Indian Sandstone Variants in Export Markets

Kandla Grey Sandstone

Kandla Grey remains one of the most consistent & widely exported Indian sandstone varieties. Its neutral grey tones work across modern and traditional projects. Importers prefer Kandla Grey for large or repeat orders because quarry availability is stable and batch matching is generally easier to manage.

Raj Green Sandstone

Raj Green sandstone features a mix of green, grey, and brown tones. It is commonly used in garden paving and heritage-style projects where variation is acceptable, and often desired. Landscapers favour Raj Green because it blends naturally with planting and outdoor surroundings.

Autumn Brown Sandstone

Autumn Brown is recognized for its warm, earthy appearance. The stone tends to develop character over time rather than losing it, which is why it is popular for patios, residential projects, and hospitality landscaping.

Mandana (Mandana Red) Sandstone

Mandana sandstone offers red-brown shades with strong visual impact. It is frequently used in courtyards, traditional architecture, and accent paving areas. From a performance standpoint, Mandana sandstone provides good compressive strength and durability.

Technical Factors Importers Commonly Review

Beyond appearance, professional buyers look at basic performance indicators to ensure the stone will meet local standards and site conditions.

Typical Technical Properties of Indian Sandstone

Property | Typical Range | Why It Matters |

Compressive Strength | 60–120 MPa | Load-bearing reliability |

Water Absorption | 1.5% – 3.5% | Freeze–thaw resistance |

Bulk Density | 2.2 – 2.5 g/cm³ | Overall durability |

Abrasion Resistance | High | Traffic suitability |

Slip Resistance (Riven) | Naturally high | Safety for outdoor use |

Actual values vary by quarry and sandstone type. For large-scale or regulated projects, importers usually request quarry-specific test reports.

Common Export Sizes and Thicknesses

Product Type | Common Sizes | Thickness |

Sandstone Slabs | 600×600 mm, 900×600 mm | 22 mm, 30 mm |

Sandstone Paving | Mixed-size sets | 22 mm calibrated |

Driveway Paving | Project-specific | 30–40 mm |

Experienced exporters can also supply custom sizes, edge profiles, and finishes when required.

Why Importers Choose Regatta Universal Exports

For importers, sourcing stone is about more than price. Delays, inconsistent colour, poor packing, or missing documentation can quickly become costly.

With over 25 years in the Indian natural stone trade, Regatta Universal Exports operates with the kind of routine that only comes from repetition. Manufacturing, finishing, and packaging are handled within a single workflow, which helps avoid the inconsistencies that often arise when too many parties are involved. Importers who place repeat orders usually value this more than anything else—the stone is consistent, the process is hassle-free, and timelines are set based on actual production capacity rather than estimates.

Closing Note

Indian sandstone has remained in international circulation for a simple reason: it holds up once laid. Stones like Kandla Grey, Raj Green, Autumn Brown, and Mandana are still being ordered year after year because there is no better option available in the market. For importers, the bigger variable is rarely the material itself. It is usually the supply chain behind it, and whether the exporter understands how minor inconsistencies can become expensive problems later.