Get to know everything about slate stone and its application in the world of architecture

January 31, 2024 AdminThe visual profile of slate stone reflect an astonishing tradition and complex aesthetics. If following the bygone period, the use of slate as a roofing material started as early as 1300 A.D. However, it was not until the 1800s that natural stone became widely used in architecture. During that time, quarrying techniques improved to provide a sufficient supply at reasonable costs.

When slate tiles were first applied to roads and canal systems in the 1870s, their popularity grew. Whether you are looking to consider slate for various architectural applicants or want to increase your knowhow about slate, this post would explain every single point you should know about this beautiful yet striking natural stone.

What is slate stone?

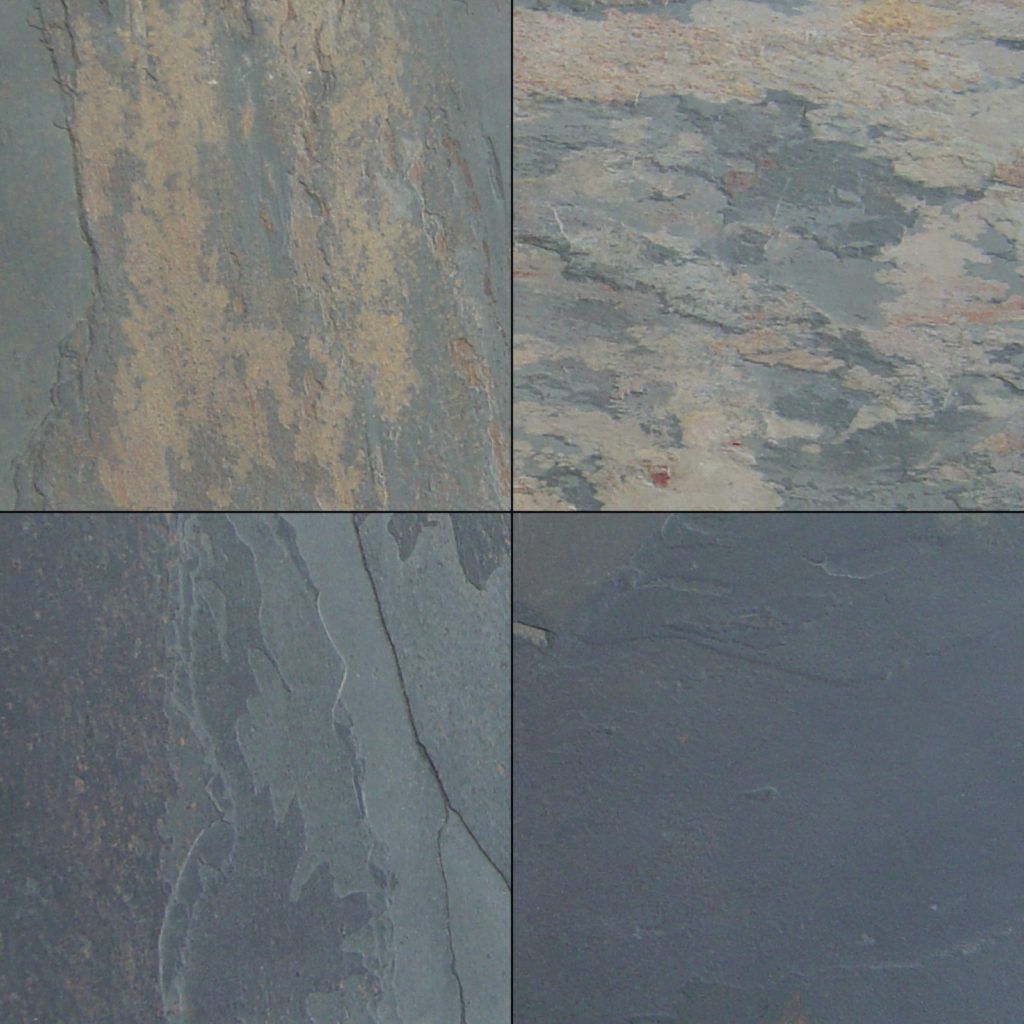

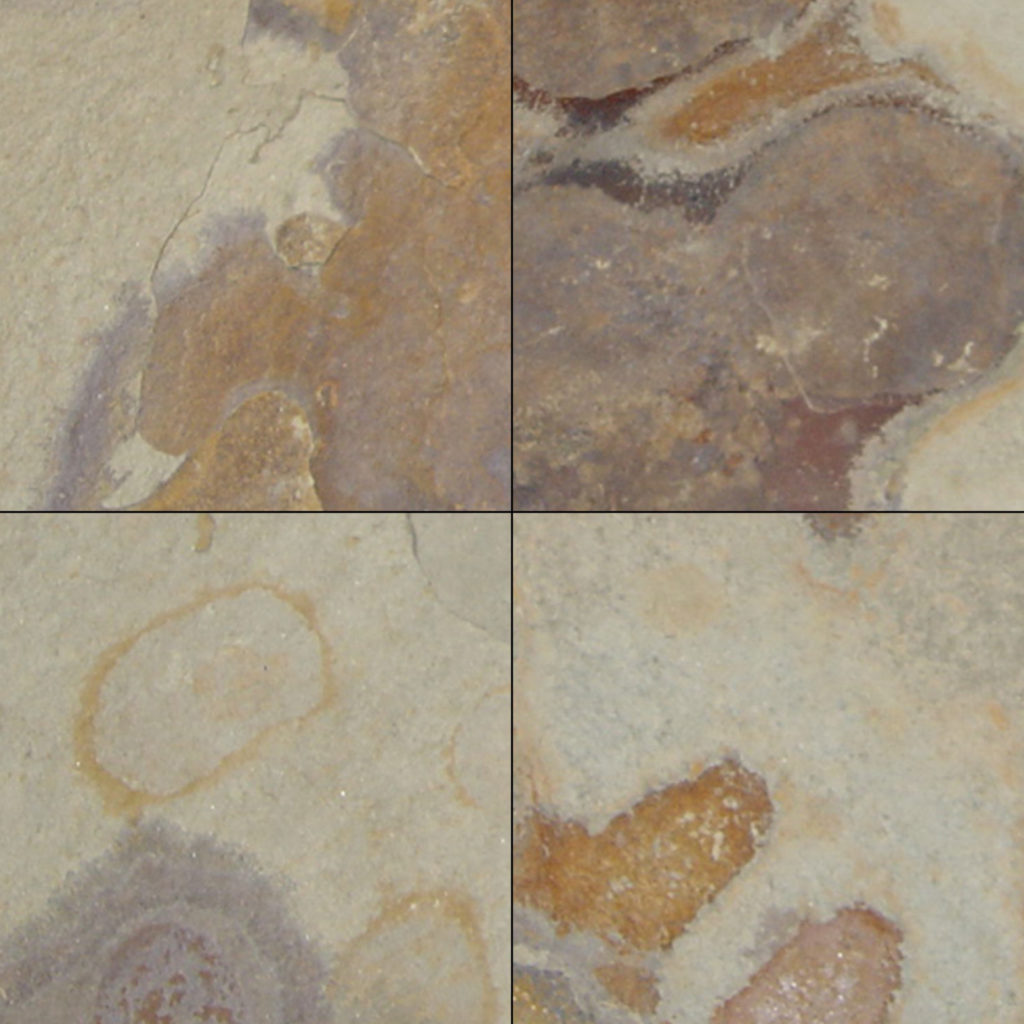

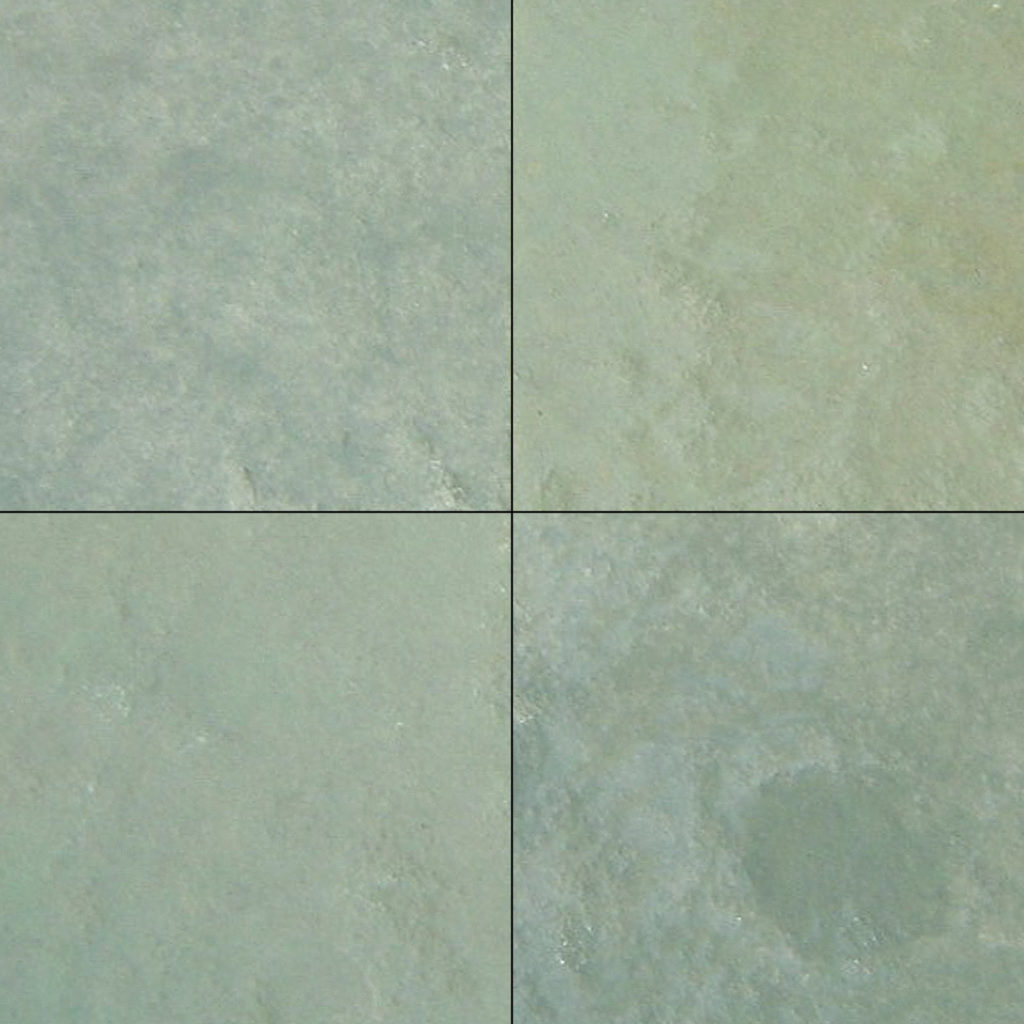

Slate is a homogenous, fine-grained metamorphic rock that is foliated—a term used in geology to describe a layering or composed structure. It is generally available in a wide range of grey tones, although it may also be purple, green, or cyan.

Although it is mostly mined in Brazil and Spain, it is also frequently found in the United States, the United Kingdom, and India. Slate tiles are still among the most beautiful and long-lasting materials to use for a structure’s remodelling or décor since they have been used for flooring, paving, and roofing for many centuries.

Origin of Slate

Naturally, slate is created by regional metamorphism, primarily at low temperatures and pressures, which modifies a sedimentary rock of the shale type, which is composed of clay or volcanic ash. Its foliation, known as slate cleavage, is the finest grained foliated metamorphic rock. Slate splits into lovely, flat sheets when cut with the appropriate equipment in the quarry along the foliation; these sheets are then readily processed into tiles for a variety of applications.

Slate is primarily composed of quartz and muscovite, with other minerals such as hematite or chlorite (which give slate its purple or more reddish hues) and chlorite (which is abundant in slate and gives it its green colour). Iron sulphide is primarily responsible for the slate’s darker hues.

It’s important to note that while certain slate tiles can fade in colour when exposed to the elements, other slate is known as “unfading” and will not alter in colour.

Slate is chosen for a variety of building applications, including pavement, facades, and roofs, because to its inherent beauty and longevity. Because of its extremely low water absorption index, it is almost impervious to freezing and frost.

Professional builders like to use slate for roofing and other building projects because it is incredibly durable and requires very little upkeep over decades. Slate is ideal for roofing since it is energy-efficient and fire-resistant. Unfortunately, due to its high cost, not everyone could afford to get one. In the past, it was also used to construct walls, which in addition to being sturdy, had a nice appearance.

Slate Quarries

Slate is mostly extracted or quarried by extracting stone slabs or strata from a designated geological deposit. Spain is the primary producer of slate in Europe and the globe. The world’s second-largest producer of slate is Brazil. However, the countries like China and India also produce top quality slate stone that is sent to the western country through several slate stone exporters in India.

How the slate is extracted?

Depending on the origin, different quarrying processes are used, but the general procedure remains the same. Finding or making breaks in the stone is the first step, followed by its removal, transportation in heavy-duty trucks, and storage at a location where it may be processed further. Any new quarry must first clear any overgrowth or surplus dirt off the deposit’s face in order to reveal it.

After that, the slate can be removed with a little explosive charge or the stone can be split with a diamond belt saw. Slate slabs may be separated with the use of steel wedges because of their noticeable cleavage. The parts may be transported and range in size and weight.

The chunks may be removed from the quarry using front-end loaders, dump trucks, and other large gear. They vary in size and weight. Depending on its intended use, slate may undergo further processing after extraction. This might entail preliminary splitting and cutting, finishing, and further shaping or cutting.

processing. The stone can also be shaped to a certain size and given an extra treatment to give it a polished, honed, or thermal-treated finish for different uses.

Using a circular blade saw, diamond wire saw, or splitter, the slate must first be cut and divided into slabs and tiles. After the stone has taken on the required shape, it can be broken into tiles manually using a hammer and chisel or automatically or partially automatically using splitting machines. Thus, the natural tiles may be utilised for roofing, for example, without undergoing any additional processing. The stone can also be shaped to a certain size and given an extra treatment to give it a polished, honed, or thermal-treated finish for different uses.

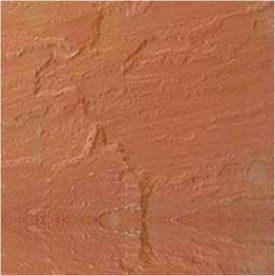

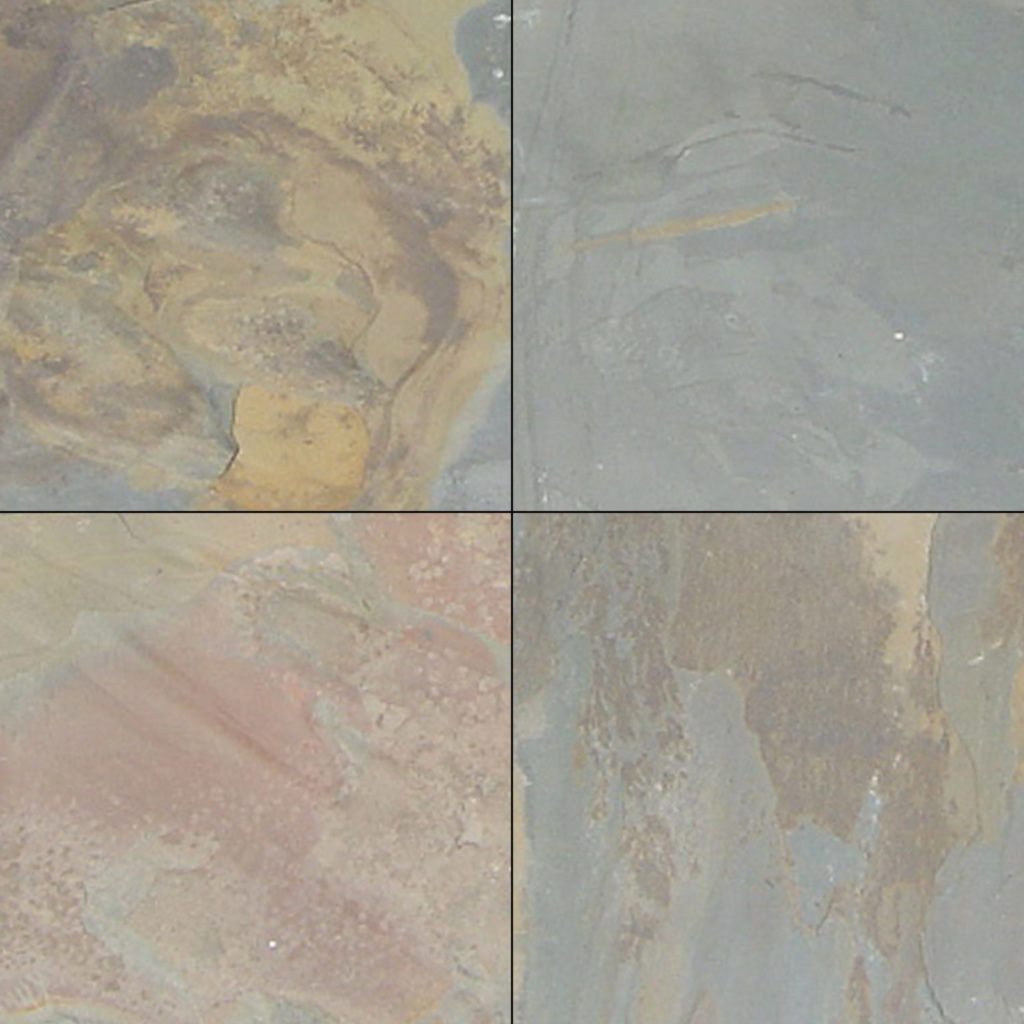

Top Indian Slate Stones

Applications of Slate Tiles

Slate has been widely utilised in construction for a very long time, as was already said, for walls, roofing, and other surfaces. Still, the stone served other functions as well. Slate was used in schools in the 18th and 19th centuries for individual writing slates, which were written on using chalk or slate pencils. It’s interesting to note that slate is also used to make pool tables. It is a very good choice since it doesn’t distort like other materials used to make pool tables. A 1 inch (2,5 cm) thick polished slab with a beautiful finish is used by the manufacturers, and it is covered in fall. However, the cost of delivery for these pool tables is high because of their weight.

Slate Stone Walls

Slate has been widely utilised in construction for a very long time, as was already said, for walls, roofing, and other surfaces. Still, the stone served other functions as well. Slate was used in schools in the 18th and 19th centuries for individual writing slates, which were written on using chalk or slate pencils. It’s interesting to note that slate is also used to make pool tables. It is a very good choice since it doesn’t distort like other materials used to make pool tables. A 1 inch (2,5 cm) thick polished slab with a beautiful finish is used by the manufacturers, and it is covered in fall. However, the cost of delivery for these pool tables is high because of their weight.

Slate Countertops

The most important characteristics of the perfect natural stone countertop are stain resistance, low water absorption capacity, and long-lasting durability. Slate stone has all of these characteristics by nature and comes in a variety of distinct hues and textures. Additionally, it provides a glossy finish for a wet appearance or a matte finish for a rough appearance. When it comes to aesthetics, slate is significantly distinct from other countertop materials. A slate countertop adds a sophisticated and fashionable touch to a kitchen or bathroom. In order to complement your countertop, the stone may also be used as a washbasin because it is waterproof. For example, if you’re a fan of the farmhouse kitchen look, go for wooden cabinets with a dark slate countertop and sink.

Slate Fireplaces

Slate slabs, which come in both small and big sizes, work well for fireplace hearths. Slate fireplaces are quite durable due to their sturdy qualities. It often turns into a visually arresting centre piece for any living area. You could want to go with the stone slabs for a touch of royalty. There is, however, good news if you’re searching for a low-cost getaway. Another in expensive option for creating a fireplace is to utilize slate tiles.

The Conclusion

Being a beautiful and sturdier natural stone, slate stone has been used extensively in numerous architectural applications from roofing to countertops, fireplaces, and others. Regatta Universal Exports is among the top slate stone exporters in India and supply all types of slates stones to natural stone importers across the world. Some of the most selling slate stones are Multi Pink, Red Gold, M Green, Black, India Autumn, Vijaya Gold, etc.