Stone of the month: Copper Quartzite

September 14, 2022 AdminIndia is a hotbed of a variety of natural stones like marble, granite, sandstone, limestone, quartzite, and others. The stones extracted from the quarries are of superior quality and available in diverse colors, sizes, and finishes. This is the reason why natural stone importers, architects, and construction contractors look toward Indian natural stone exporters when it comes to obtaining genuine, qualitative stones.

Among various natural stones found in India, quartzite is a popular natural stone and found mainly in the various states of India like Haryana, Chattisgarh, Rajasthan, Jharkhand, Madhya Pradesh, Karnataka, and Himachal Pradesh. This stone is primarily used for construction activities all across the world.

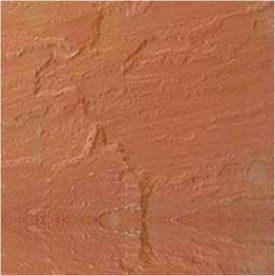

Some of the commonly extracted quartzite stones in India are H Green, Ocean Green, Silver Shine, H White, S White, Z Green, Copper, Golden, D Green, and others. Among them, Copper or Deoulli Yellow is a widely exported quartzite from India. The reasons are its excellent looks, amazing durability, and unmatched heat resistance. These qualities make it an apt choice for both indoor and outdoor construction applications.

Wall cladding copper quartzite

Copper Quartzite features a dark backdrop with streaks and patterns of pale reddish-brown color running over it.

Quartzite is well-known for its consistent strength, toughness, and slip-resistant properties. This stone has the potential to withstand the worst weather conditions while also increasing the value and aesthetic appeal of any home. The Federal Building in Sioux Falls, South Dakota was made using quartzite from local quarries.

What is Quartzite?

When sandstone undergoes metamorphosis, quartzite (from the German Quarzit) is created. Its high quartz concentration is also implied by the word quartzite. Quartz makes approximately 90% of the volume of most quartzites, although in the purest types of quartzite, the ratio can reach 99%.

Quartzite resembles its parent rock in appearance, although it is significantly more durable than sandstone. Breaking it is the greatest technique to distinguish quartzite from sandstone.

Quartzite is a naturally occurring stone that often comes in whites and greys with sporadic beige as its base color. The stone’s variety of hues, which are patterned all over, are what really make it beautiful. Quartzite may take on hues of pinks and reds, mixtures of blue, copper, and sea green when iron oxides and other minerals are predominant.

Because of various minerals present during the metamorphosis of sandstone, certain quartzites have colors such as purple, brown, and black.

The major applications of quartzite are flooring, wall cladding, building stone, ornaments, monuments, pool coping, sills, and paving stone.

Major Features of Copper Quartzite

- An extremely durable natural stone

- Boasts superior hardness

- An unmatched premiumness

- Available in diverse sizes and finishes

Mining of Copper Quartzite in India

The quartzite quarries in the Deouli region of the state of Rajasthan are known to produce this yellow-colored quartzite. Several natural stone quarries boast the landscape, yielding different types of quartzite, including Copper Quartzite.

It’s important to note that because these stone processing facilities are located close to quarries, B2B tile buyers all over the world benefit from cost reductions. The stone is prepared using a number of tools in a variety of ways, making it appropriate for both indoor and outdoor use.

One of the top manufacturers of Copper Quartzite is India. High-quality quartzite is exported from the nation by a number of quartzite exporters and producers to nations including the United States, the United Kingdom, the United Arab Emirates, Denmark, Norway, Australia, Germany, and others.

Processing Unit

Cutting the raw blocks into standard and custom-sized slabs is the next stage of Copper Quartzite processing. The slab’s specific dimensions are determined by the type of stone used. Gangsaw slabs and cutter slabs are the most common types of slabs. Tiles, on the other hand, can be made on demand.

Quartzite is further processed using special blades and gear that turn blocks into slabs of various sizes. Quartzite manufacturers and exporters can now save money and time while boosting quality thanks to recent improvements in the natural stone processing business.

This level of processing is done to bring the quartzite as close to perfection as possible before it is employed. Another advantage of this process is that it makes transportation quicker and simpler.

Finished Material

The most crucial thing to keep in mind is that quartzite may be processed in a number of different ways to provide different surface qualities. The exact application of the stone after processing determines the final eventual choice. The most common surface treatments for quartzite tiles are as follows:Natural

- Polished

- Brushed

- Honed

Sizes

The most standard sizes of Copper Quartzite tile are:

30 X 30, 60 X 30, 60 X 60 AND 60 X 90 CM with thickness varying between 1 and 3 CM.

The Conclusion

Be it a residential project or a commercial one, Copper Quartzite is a wonderful option for a range of applications. Its premium color tone is second to none and offers a stupendous look to the structure when used. India is a leading manufacturer of copper quartzite and other types of quartzite.