Stone of the month: Kota Desert Sandstone

February 21, 2022 AdminIndia is known to be a leading source of various natural stones like granite, marble, sandstone, limestone, slate, quartzite, and others. There are many quarries located all across the country that produce high-quality stones that are exported to other countries. One such popular stone is Kota Desert Sandstone. Found in the Northern part of the country, this neutral-shade sandstone is a widely preferred sandstone in both residential and commercial applications.

In recent times, the demand for sandstone has increased due to its amazing properties like hardness, weather resistance, durability, and versatility. Mostly, sandstone is used for wall cladding, garden paving, flooring, countertops, sinks, monuments, pool coping, and others. There are different types of sandstones that come from the Northern part of the country and Kota Desert Sandstone is one of them.

Sandstone is largely admired because of its regular strength, toughness, and slip-resistant quality. This stone has the capability to counter the worst climates, increase the value and visual quotient of any property. One of the most striking usages of sandstone usage can be seen in the architecture of Petra. The sandstone coatings in Petra were the prime factor of the location and the architectural detailing.

What is Sandstone?

Sandstone refers to a sedimentary rock that is made up mostly of quartz sand. However, it may also contain considerable amounts of feldspar, and often clay and silt and clay. Sandstone that is made up of more than 90% quartz is known as quartzose sandstone.

On the other hand, the sandstone that has more than 25% feldspar, is arkose or arkosic sandstone. Moreover, if there is a substantial amount of clay or silt, it will be termed argillaceous sandstone.

The color of sandstone differs greatly, given its composition. Argillaceous sandstones’ colors range from blue to gray. As it includes light-colored minerals, sandstone is characteristical of a light tan shade. Other things, however, also determine the colors of sandstone. The most common sandstones contain different shades of red that are due to the presence of iron oxide (rust). In some cases, they may have a purple color due to manganese.

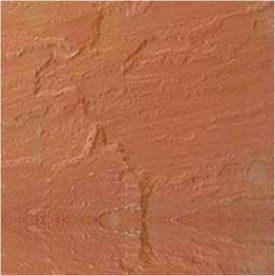

Featuring a brown and beige color scheme, Kota Desert Sandstone contains several linear quartz lines with traces of golden yellow-brown tones. This natural stone is primarily known for its hardness, longevity, and capability to counter harsh weather conditions. It is chiefly used in architectural applications like flooring, paving, pool surrounds, and wall cladding.

Major Features of Kota Desert Sandstone

- Hard-wearing stone ideal for multiple applications

- Exhibit exceptional hardness

- Tougher and durable

- Available in different finishes and sizes

Mining of Kota Desert Sandstone in India

This beige-colored sandstone is essentially extracted from the sandstone mines found in the Kota region of the state of Rajasthan. The region is full of several natural stone quarries that produce different types of Indian sandstone including Kota Desert Sandstone.

It is important to note that these stone processing units are located close to the quarries. In other words, it results in cost savings, that are then passed on to the B2B tile buyers globally. A number of machines are used to process the stone in different ways which make it useful for various indoor and outdoor applications.

India is known to be one of the biggest producers of Kota Desert sandstone. There are several sandstone suppliers and exporters in the country that provide high-quality sandstone to the countries like the USA, UK, UAE, Australia, Germany, and others.

Processing Unit

The next processing stage of Kota Desert sandstone processing is to cut the rough blocks into standard and custom-sized slabs. The exact dimension of the slab relies on the exact stone application. The most usually obtained slabs are gangsaw slabs and cutter slabs. However, when required, tiles can also be produced.

For the further processing of sandstone, special blades and machinery are employed, that convert blocks into different sizes of slabs. Above all, the latest advancements in the natural stone processing industry have enabled sandstone manufacturers and exporters to save both cost and time while improving the quality.

This level of processing is done to make the sandstone close to perfection before the final usage. In addition, another benefit of this step is to make the transportation of slabs easier.

Finished Material

One most important thing to keep in mind is that there are hundreds of ways sandstone can be processed to deliver a specific surface finish. The eventual selection of a particular finish depends on the exact application of the stone after its processing. The most widely adopted sandstone surface finishes are:

- Natural

- Brushed

- Bush hammered

- Honed

- Tumbled

- Sandblasted

Sizes

The most standard sizes of Kota Desert Sandstone are:

- CUTTER SLAB 120-190 CM X 90-60 CM

- TILES 30 X 30, 60 X 30, 60 X 60 AND 60 X 90 CM

- PALISADE 10-12 X 12-25 X 30-250 CM

- WALL CLADDING 100 X 25-45 X 5 CM

- STEP BLOCKS 75-200 X 35 X 15 CM

- THICKNESS 2-6 CM

Finishes

Surface finishing is of tremendous value as it helps architects discover all the chattels of the stone material precisely. However, there are loads of reasons why surface finishing has an important role to play. These include:

Some most common surface finishes of Kota Desert Sandstone are:

- Natural calibrated machine cut and hand-cut

- Natural brushed machine cut and hand-cut

- Brushed calibrated machine cut (MC) and hand-cut tumbled

- Honed calibrated machine cut and hand-cut

- Honed +sandblasted calibrated machine cut and hand-cut

- Bush hammered calibrated machine cut

The Conclusion

The yellowish color tone of Kota Desert Sandstone gives it a remarkable visual character that is second to none. In addition, the multi-faceted application of this sandstone makes it a wonderful solution for modern construction.