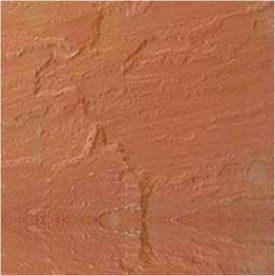

Stone of the month: Toskana Sandstone

January 28, 2022 AdminMainly known for its multi-color appearance, Toskana Sandstone is a widely popular sandstone worldwide. Be it residential construction or a commercial one, this sandstone exhibits superb performance in all scenarios without presenting any downside. Due to its natural and subtle looks, this Indian sandstone remains the most preferred choice of contractors, architects, builders, garden pavers, and property owners globally.

Sandstone is largely admired because of its regular strength, toughness, and slip-resistant quality. This stone has the capability to counter the toughest climates, augmenting in value and visual appeal over years. One of the most remarkable examples of sandstone usage in architecture is Petra. The sandstone coatings in Petra were the prime factor of the location and the architectural detailing.

What is Sandstone?

As the name indicates, sandstone is made up of sand-sized grains of rock fragments, and specific minerals are broken originating from other, primitive rocks. Most of us understand how big sand grains usually are from our experience visiting the beach or enjoying games in a sandbox. Geologists also understand that sand-sized grains tend to boast a specific measurement, from about 1/16th of a millimeter to 2 millimeters. Sandstone is found to have two big applications – dimension stone and dimension stone.

Dimension stone means any rock material that can be processed into precise sizes, typically in the form of blocks and slabs. On the other side, crushed stone is primarily meant to be used in the development of different structures like roads, bridges, roads, and numerous other residential and commercial elements.

Boasting the strong impressions of grey, brown, and camel dust colors on its surface, Toskana Sandstone is a visually-appealing multi-colored sandstone from India. The most amazing things about this Indian sandstone are its hardness, lasting ability, and ability to withstand harsh weather conditions. It is mainly used in architectural applications like pool surrounds, flooring, paving, and wall cladding.

Major Features of Toskana Sandstone

- Multi-colored sandstone with the amazing weather-resistant capability

- Extremely hard stone as compared to other choices

- Stronger and durable

- Comes in numerous surface finishes

Mining of Toskana Sandstone in India

This multi-colored natural stone is actually sourced from the sandstone mines located in the Bijolia region of the state of Rajasthan. The region is known to have a large number of stone quarries that provide high-quality sandstone including Toskana Sandstone.

The sandstone is mined in the form of big-sized stone blocks that are further moved to dedicated natural stone processing units where the next stage of processing is carried out using a number of power-driven machinery.

Since India is a leading producer of Toskana sandstone, there are many sandstone exporters in the country that process and export different types of sandstone to other countries.

Processing Unit

The next stage of Toskana sandstone processing is inclusive of cutting the sandstone blocks into fixed-sized slabs. The exact dimension of the slab depends on the exact application of the stone. The most commonly done slabs are cutter slabs. However, if processed further, sandstone tiles can also be obtained.

To process the sandstone, special blades and machinery are used to convert blocks into slabs of differing shapes and sizes. In addition, these slabs are processed at the next level to procure tiles of varying dimensions. The newest advancements in the natural stone processing domain have allowed sandstone manufacturers to save high amounts of cost and time while ensuring perfect results

The most important objective behind this kind of sandstone processing is to attain a high degree of precision in the processed sandstone slabs. They can be additionally used for different construction applications. In addition, it makes the transportation of these slabs to another location easier. From utilizing highly advanced stone processing equipment to using small hand-held tools like mauls and axes, Indian sandstone exporters use different types of tools and equipment to obtain the stone in a particular size and finish.

Finished Material

One crucial thing to remember is that the sandstone can be processed to attain a particular surface finish. The final choice of a specific finish rests on the precise application of the processed stone. The most common sandstone surface finishes are:

- Natural

- Brushed

- Bush hammered

Sizes

The most usual sizes of Toskana Sandstone are:

- CUTTER SLAB 120-190 CM X 90-60 CM

- TILES 30 X 30, 60 X 30, 60 X 60 AND 60 X 90 CM

- PALISADE 10-12 X 12-25 X 30-250 CM

- WALL CLADDING 100 X 25-45 X 5 CM

- STEP BLOCKS 75-200 X 35 X 15 CM

- THICKNESS 2-6 CM

Finishes

Surface finishing is of extreme importance as it helps architects explore all the properties of the stone material clearly. There are hundreds of reasons why surface finishing has the best say. These include:

⦁ It turns the stone slip-resistant.

⦁ It gives the surface a high reflection.

⦁ It changes the color of natural stone.

⦁ It also softens and intensifies the white color.

Some most common finishes of Toskana Sandstone are:

- Natural calibrated machine cut and hand-cut

- Natural + brushed machine cut and hand-cut

- Natural + brushed calibrated machine cut and hand-cut tumbled

- Honed calibrated machine cut and hand-cut

- Honed +sandblasted calibrated machine cut and hand-cut

- Bush hammered calibrated machine cut

The Conclusion

Due to its dynamic, multi-colored visual presence, Toskana Sandstone emerges as the foremost choice for various applications like paving, wall cladding, and pool surroundings. Its amazing weather-resistance features make it an ideal choice for both hotter and colder climates.

Since India is a hub of different types of sandstone, getting high-quality Toskana Sandstone from India is simple, reasonable, and valuable.